Problems at the floodgates - Part 2

Part 2: Workplace Safety

The security situation at the floodgates would be bad enough if it were the only problem. But - at least at 17th Street, which is the only site still under construction - apparently normal workplace safety measures required by OSHA don't apply. Just to ensure I'm on steady ground here, I looked at the contract solicitation for the 17th Street Canal. On page 81 (Adobe Acrobat page 112), it says (in part):

29CFR1926 is safety standards for a construction site. 29CFR1910 is general workplace safety standards for any workplace."...On contracts for construction or dismantling, demolition, or removal of improvements, the Contractor shall-

(1) Provide appropriate safety barricades, signs, and signal lights;(2) Comply with the standards issued by the Secretary of Labor at 29 CFR Part 1926 and 29 CFR Part 1910; and

(3) Ensure that any additional measures the Contracting Officer determines to be reasonably necessary for the purposes are taken."

Does this look safe? Electric arc welders get very hot. Welding gas is (I believe) flammable. That's not a good mix. (Note: it has been pointed out since the original publication of this post that this might not be the usual position for the welding bottles - they might get moved elsewhere on the site for use.)

Gasoline is supposed to be stored remotely on a work site.

The electrical cords coming out of the generators are in terrible shape.

The first two situations appear to be in violation of OSHA regulations for storage and handling of hazardous substances on a construction site. The third is in violation of OSHA regs for safe use of electric cords on a construction site. Wires like that are supposed to be withdrawn from use.

As I mentioned briefly in Part 1, the Corps also has their own safety manual, which the contractor at 17th Street is also supposed to adhere to. The manual is EM 385-1-1. Chapter 11, which is the electrical section, has this to say about use of cables: "Patched, oil-soaked, worn, or frayed electric cords or cables shall not be used." (EM 385-1-1, paragraph 11.A.03.e). That cord (and most others on the site, according to Deep Flood) is definitely "patched."

By the way, here's another look at the second electric arc welder. Look closely at the trailer hitch.

It's not locked. Anyone could drive their truck up and steal it.

There are design errors that were not caught on drawings before they were fabricated:

Workers cannot be required to clamber over handrail to get to a ladder. Especially about 15 feet over 18 foot deep water, which these are. This is a walking-working surface violation according to OSHA regs. Specifically, 29CFR1910.27(c)(1), which says,

"On fixed ladders, the perpendicular distance from the centerline of the rungs to the nearest permanent object on the climbing side of the ladder shall be ... 30 inches for a pitch of 90 degrees (fig. D-2 of this section)"

All of the ladders from the deck up to the upper level are like this.

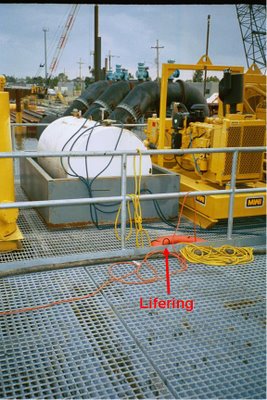

Deep Flood tells me this is the only lifering on the gate structure.

OSHA regulations say it is supposed to have at least 90 feet of rope on it. It obviously doesn't. It also doesn't appear to be tied to anything sturdy. Finally, look at what one has to do to get the thing to someone in the water. You'd have to climb over the handrail even to get to it, which is hardly "readily available," as required in the OSHA standard. This is very poor water safety. I hope none of the workers fall in the canal (the water depth is about 18 feet).

Does this look safe to you?

The reason I'm bringing all this up is because the Corps and its contractors are ignoring the well-learned lessons of the "safety pyramid."

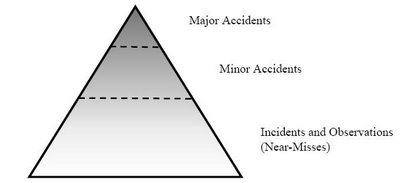

Here's an example of such a pyramid:

The safety pyramid is a tool for preventing injuries and fatalities at any workplace. The idea is that a certain number of "near misses" or minor incidents will inevitably lead to serious injuries and deaths on the job. It is only a matter of time. But if you can minimize the number of near misses and minor incidents (make the base of the pyramid smaller), you can drive the chances of death or injury to near zero. The way to do that is to take care of small violations before they become big incidents.

Considering what Deep Flood has seen, I would be surprised if there haven't been any injuries on the floodgate jobs. And from a purely financial point of view, that gets my goat, because any injury settlement comes out of the Corps' pocket. That's a pocket filled by the taxpayers, including me. On a more altruistic note, it means that many workers are being placed in harm's way unnecessarily by very poor project management.

Conclusion: the 17th Street canal floodgate site is not a safe place to work, and OSHA regulators should definitely pay the site a visit.

Next: Part 3 - the environment

0 Comments:

Post a Comment

<< Home